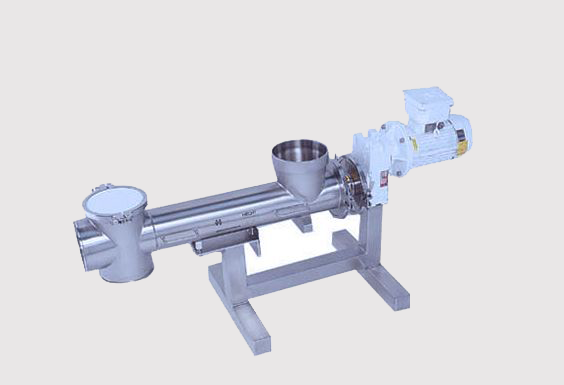

Dosing screw

Dosing screw

Dosing screw conveyors are used for dosing the exact component quantity into a weighing bin.

The material enters through the product inlet and is then gently conveyed through the screw conveyor by the helix blades. A variable frequency drive controls the throughput. Different speeds for coarse and fine dosing combine a high throughput volume and exact measuring.

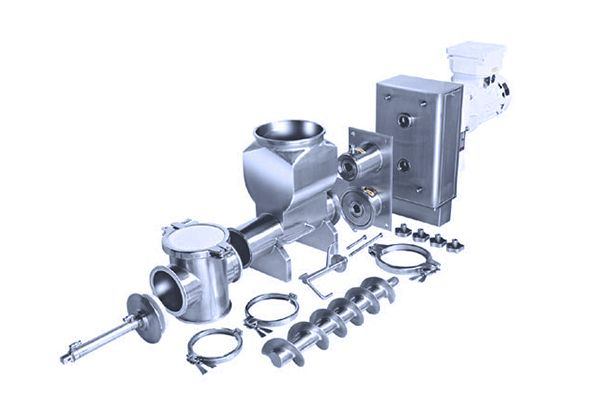

Various design implementations yield optimized solutions for various customer requirements. Examples are easy clean features, air purge fittings meeting highest hygienic standards or using the right material and surface finish for the corresponding application at hand.

Optional fast disassembly features allow for quick cleaning and inspection without the use of tools.

Various design-features for the fields of foods, chemical, animal feed and plastics yield optimized solutions for custom requirements.

Dosing Screw Conveyor Advantages

The DS dosing and conveying screw is used for dosing and conveying dry, powder and pelleted bulk materials, and for emptying vessels. In conveying systems, it is used for dosing and filling to weighing vessels The dosing and conveying screw is available with one or two outlets.

Exact dosing via speed control & flow-stop flap

Flexibility – wide range of sizes & design features

Exact design assures a clean operation

Optional fast disassembly features allow for quick cleaning and inspection without the use of tools

Hygienic Design

Uses of Dosing Screw Conveyors

-

For continuous and discontinuous conveying and metering of bulk materials in several conveying lines and scales etc.

Plastic industry

Food industry

Chemical industry

Bulk solids