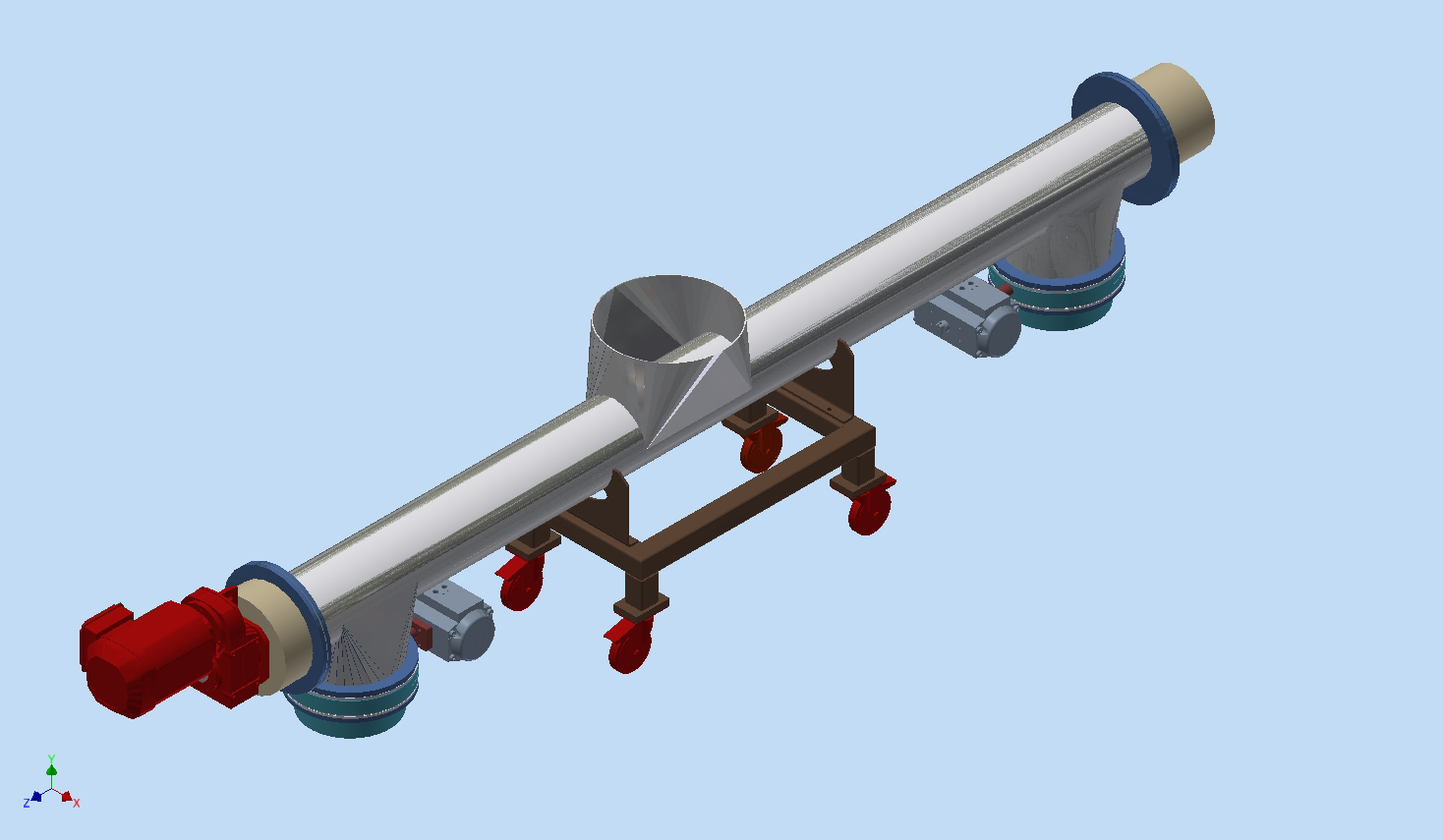

Horizontal screw conveyor

Horizontal screw conveyor

The horizontal screw conveyor is the most distributed version of the screw conveyor, thanks to its simple and easy to use design. They can convey materials at 15-45% trough loading, defined as the maximum trough capacity divided by the specified trough load for a given material. A more viscous, sluggish material will require a lower trough load, while a lighter free-flowing bulk can be fed at a higher load. Figure 2 shows the typical arrangement of the horizontal screw conveyor, where the drive unit is at the discharge end. This causes the material to be pulled towards the discharge, putting the auger sections in tension, reducing fatigue and wear on the conveyor. They are great for both free-flowing and non-flowing media and are a cost-effective option next to traditional belt conveyors. They are also perfect for homogenizing mixtures and can be left open for inspection or totally enclosed, depending upon the environment.

Horizontal screw conveyors also called as linear feeder are the most widely used type of screw conveyor. These are used to convey bulk materials from one part of a process to another. Horizontal screw conveyors are available in a wide range of sizes, lengths, configurations and material of construction.

Screw conveyors are typically designed to convey bulk materials of free flow and non-free flow type of material. This can be used as feeder for Silo for weighing purpose in gunny bags and related holding units.

Coarse and fine filling of material is possible i.e. is feeding speed can be adjusted with use of VFD.

This is very advantageous as it uses single gear box motor with continuous run,low maintenance cost, custom built as per available space which saves time, reduces manual material movement and hence increases productivity.

Advantages of Horizontal Screw Conveyors

Ideal for conveying dry to semi-fluid bulk materials – free flowing to sluggish

Cost-effective when compared to other conveying devices such as belt, pneumatic or aeromechanical

Efficiently distributes bulk materials to various locations using multiple inlet and discharge points

Totally enclosed for dusty, corrosive or hazardous environments

Metascrews is your reliable Indian supplier of industrial machinery. We are a top producer with a focus on creating machines Ribbon Blender and Mixer Machine Manufacturers in India that are tailored to the various requirements of industrial processes. Furthermore, we are excellent makers of Horizontal Screw Conveyors, offering effective material handling solutions for a range of uses. Check out Metascrews.com for high-end equipment.