Inclined Screw Conveyors

Inclined Screw Conveyors

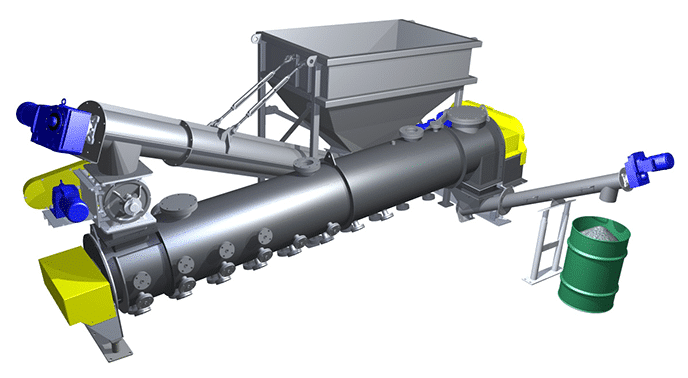

Inclined screw conveyors typically operate from slightly above the horizontal position to 45-degrees from the horizontal position. Above 45-degrees an inclined screw conveyor is considered a vertical screw conveyor and must be designed in accordance with the Metasis Engineering Guide for Vertical Screw Conveyors. As the degree of incline increases, conveying efficiency is reduced and horsepower requirements increase due to the effects of gravity and bulk material fall back. Conveying efficiency is affected by angle of incline, characteristics of the specific bulk material, type of screw conveyor trough and screw pitch. Metasis recommends designing screw conveyors using the lowest possible degree of incline for maximum efficiency.

Inclined Screw Conveyor Aplications

Inclined screw conveyors are used in a few different applications within the process industry. These applications include the agricultural, construction and food and beverage industries. They transport raw materials like cement, fertilizer, feed, sugar and meat.

Inclined screw conveyors are used to convey and elevate bulk materials from one level to another. Depending upon the bulk material and the objective, proper design and construction of an inclined screw conveyor will provide many years of uninterrupted service and productivity.

With a focus on inclined screw conveyors, Metascrews provides effective material handling solutions for a range of sectors. Being one of the largest manufacturers in India of biomass plants, we offer creative and environmentally friendly methods that boost output.