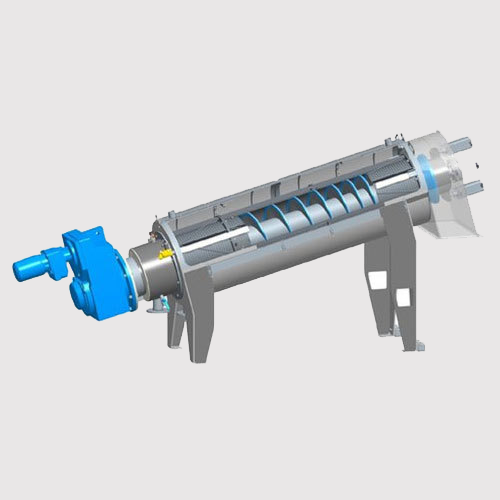

Screw Press Machine

Screw Press Machine

A screw press is used for material that is hard to dewater, including materials that pack together. The screw press uses a filter system to separate the liquid from the solid material. Liquid collects as it flows through a screen or filter and can then be reused

A screw press is a type of machine press in which the ram is driven up and down by a screw. The screw shaft can be driven by a handle or a wheel. It works by using a coarse screw to convert the rotation of the handle or drive-wheel into a small downward movement of greater force. The overhead handle usually incorporates balls as flyweights. The weights helps to maintain the momentum and thrust of the tool to make it easier to operate.

Screw Press Machine Aplications

Vertical screw conveyors are very efficient for elevating certain bulk materials; however due to the high speeds and product fallback, they are somewhat limited in the types of products to which they are best suited. Vertical screw conveyors are most effective for elevating materials that are:

-

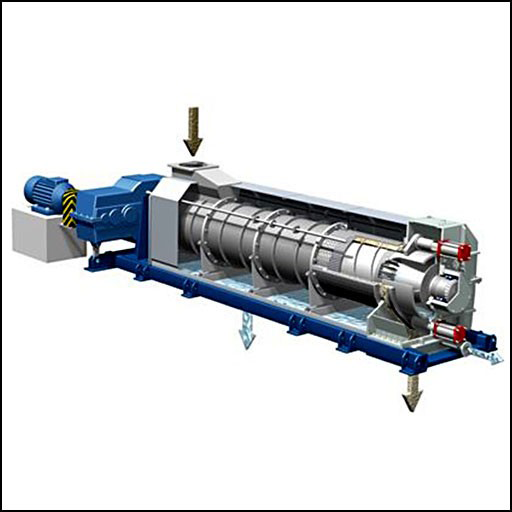

Insensitive to coarse material due to the wide gap between the screw conveyor and sieve

-

No permanent sieve cleaning required, low wash water consumption

-

Pneumatically controlled pressure cone system

-

Defined sludge residence time

-

Permanent movement of filter cake, minimized filter resistances

-

Minimum wear due to the low speed of the compacting screw

-

Minimized noise

-

Low energy consumption

-

High dewatering degrees with fibrous sludge