Metadose System

Metadose System

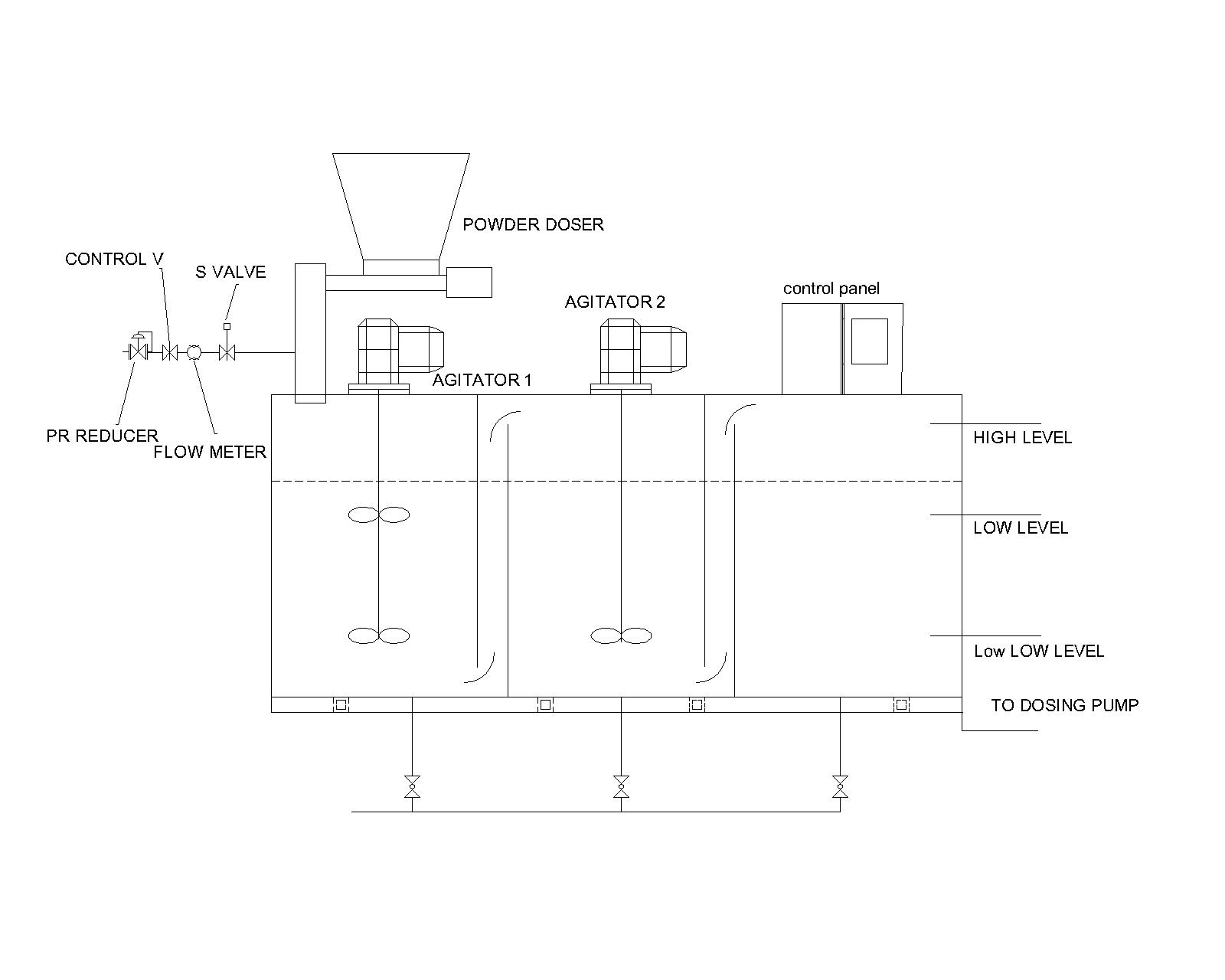

The Metadosing system is made in rectangular Tank. Tank has three compartment 1st Tank Water inlet with inlet of chemical powder and water inlet consist of two blade hub, agitator blade shape which mix powder and water slowly, avoid foaming.

Continuous solid mixer overflows to 2 nd tank where final maturation takes place required time will be 60 min to 2 hrs. Water continuously overflow 3rd chamber dosing chamber. Dosing chamber continuously supply dose to application continuously.

Complete System is fully automatic controlled by panel consist PLC, HMI and VFD. Panel is connected with various sensors such as level of tank, flow rate of water, flow of poly powder etc. and it automatically operate system as per required logic implemented.

When low level achieved in dosing tank then polymer preparation will be start .and it continuously flow from Tank 1 to tank three with ensuring final matured informed mixer goes to dosing tank.

To handle solid powder system is connected with screw with connected Hopper of 50 liters capacity and hopper ensure complete drain in screw. Screw is controlled by VFD by adjusting frequency speed can be varied and required flow rate is set as per requirement. Complete screw body covered outside by ceramic band heater

Also water feed line consist of flow pressure reducer and flow sensor to measure flow of inlet water.

Metadose System Aplications

Schematic Arrangement of System having following applications:

-

Decanter, separator and filter press to improve dewater process

-

Flocculation in Water treatment, Physico Chemical treatment

-

Flocculation in Water treatment, Physico Chemical treatment

1. Sludge Preparation:

2. Water and Waste water:

3. Paper Industry:

System Logic

1. When dosing compartment where dosing pump connected, its volume reach at 30% or below

Zthen Dosing Pump will off,

Inlet water Pump will on and 2 min delay Powder doser will be on

2. When level of dosing compartment at 10 percent then dosing pump will off

3. When dosing tank compartment at 80 Percent of dosing volume then screw doser will off and water inlet will be off

4. If Hopper Level at its 2 % volume then screw doser will be off, water inlet off and alarm to feed Inlet Hopper.

Dosing System

Meta dosing system are highly efficient to make solution Polymer or flocculants, which ensure accurate and optimum preparation.Systems are fully automatic and tested, it improves the separation process between solid/Liquid phases used in various applications..

System consist of

Schematic Arrangement of System having following applications:

-

0.5 Hp Gear Motor and 50 Ltrs standard Hopper (SS316 OR SS304)

-

Consist of pressure reducing valve, Flow Meter, control valve and solenoid valve

-

Digital control Panel inside parts as per customer brand requirement

-

Rectangular Tank with compartment ( FRP,PP or SS04,Orss316) as per requirement

-

First Tank SS 316 with two blade Hub

-

Maturing tank SS 316 1no

-

Dosing compartment agitator Optional

-

Each tank with Draining Option Available

-

Inlet Pump and outlet dosing pump are optional